KDG303: Ultra-fine carbide substrate with high strength, toughness and wear resistance, in combination with nano-structured nc-TiAlN coating aiming at optimizing drilling operations, makes sure the tools have very high toughness and hardness. Unique coating technology gives the tools smooth surface and excellent wear resistance, and outstanding thermal stability and chemical stability provide effective protection for the cutting edge.GD series have a wide applications range. There are some features as the following: 1. Versatile, for high efficiency machining in a variety of material e.g. P(steel), M(stainless steel), K (Cast iron). 2. Linear cutting edge with high strength. Optimized drill point structure for better cutting performance. 3. Simulation in combination with testing for superior overall performance. 4. Professional after treatment for coating ensures low-resistance high-efficiency machining. 5. Double edge-line design for improved machining stability.

KDG303: Ultra-fine carbide substrate with high strength, toughness and wear resistance, in combination with nano-structured nc-TiAlN coating aiming at optimizing drilling operations, makes sure the tools have very high toughness and hardness. Unique coating technology gives the tools smooth surface and excellent wear resistance, and outstanding thermal stability and chemical stability provide effective protection for the cutting edge.GD series have a wide applications range. There are some features as the following: 1. Versatile, for high efficiency machining in a variety of material e.g. P(steel), M(stainless steel), K (Cast iron). 2. Linear cutting edge with high strength. Optimized drill point structure for better cutting performance. 3. Simulation in combination with testing for superior overall performance. 4. Professional after treatment for coating ensures low-resistance high-efficiency machining. 5. Double edge-line design for improved machining stability.

Boring tools over view

Boring tools over view Drilling tools overview

Drilling tools overview

Coated grade: KDG3013 New AlCrN substrate composite coating, with excellent abrasion resistance and bonding resistance, improves the stability of the insert edge. Unique coating after-treatment technology effectively reduces the cutting resistance for smoother chip evacuation and higher security.

Coated grade: KDG3013 New AlCrN substrate composite coating, with excellent abrasion resistance and bonding resistance, improves the stability of the insert edge. Unique coating after-treatment technology effectively reduces the cutting resistance for smoother chip evacuation and higher security.

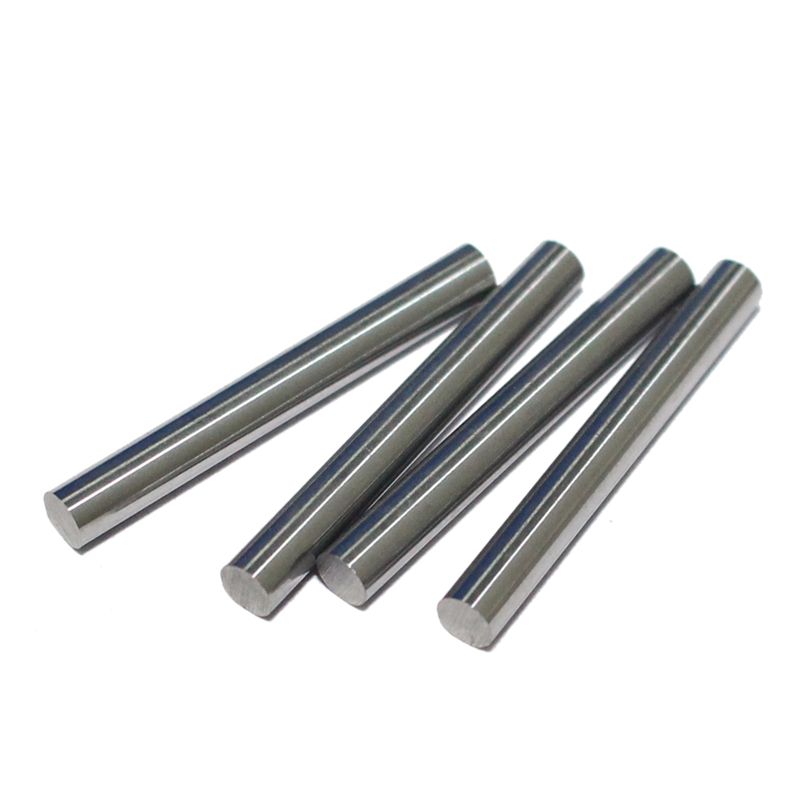

| Drills | Solid carbide drills |

| Indexable shallow drills | |

| Reamers | Solid carbide reamers |

| Threading cutters | Solid carbide threading cutters |

| Solid carbide threading mills |