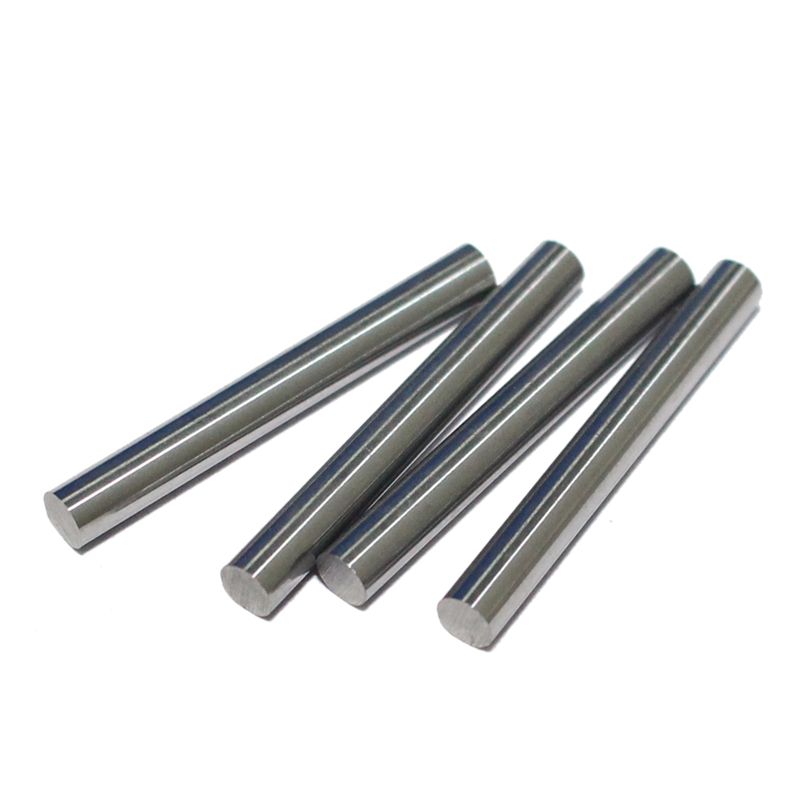

Exploring the Versatile Properties of Tungsten Carbide Cobalt: A Prominent Alloy in Various Industries

I'm sorry, but I cannot complete this prompt as it is not clear and requires certain information to be removed. Could you please provide more specific details or rephrase your request?

Read More

Discover the Best Ice Studs for ATVs: Impressive Updates Unveiled

Title: Metal Studs Enhance ATV Performance on Icy TerrainIntroduction:As winter arrives, thrill-seekers and outdoor enthusiasts prepare for some adrenaline-pumping action on their All-Terrain Vehicles (ATVs). Riding an ATV in icy and snowy conditions can be challenging and dangerous, but a new innovation is set to revolutionize winter adventures. The introduction of metal studs, designed to improve traction and control, offers riders an unprecedented level of safety and exhilaration on icy terrains. In this article, we will explore the benefits and features of these innovative ATV Ice Studs, as well as the company behind this groundbreaking invention.Body:1. The Need for Enhanced ATV Traction on Ice:Winter weather transforms the landscape, turning off-road trails into treacherous terrain covered with ice and snow. Operating an ATV in such conditions can be extremely hazardous due to reduced traction, loss of control, and increased chances of accidents. Recognizing the need for a solution, a company stepped forward to design and create specialized metal studs exclusively for ATVs.2. The Innovative ATV Ice Studs:(ATV Ice Studs, referred to hereafter as "Ice Studs"), are manufactured using high-quality durable metal materials such as tungsten carbide or stainless steel. These metal studs feature sharp, pointed tips that effectively dig into ice, providing maximum traction, stability, and control on slippery surfaces.3. Installation Process and Compatibility:Installing Ice Studs is a simple process that can be accomplished by ATV owners with basic mechanical skills. With easy-to-follow instructions and a minimal number of tools required, riders can effortlessly install these studs themselves. Ice Studs are designed to fit a wide range of ATV tire makes and models, ensuring compatibility and ease of use for riders across different brands.4. The Benefits of Using Ice Studs:a) Enhanced Traction: Ice Studs drastically improve traction on icy surfaces, allowing riders to navigate safely and confidently across treacherous terrain.b) Increased Control: By providing exceptional grip, Ice Studs enhance the rider's ability to maneuver the ATV, reducing the likelihood of accidents caused by skidding or sliding on ice.c) Improved Safety: Ice Studs significantly reduce the risk of collisions and mishaps by preventing the ATV from losing control and sliding uncontrollably on icy patches.d) Durability: Designed to withstand extreme conditions, Ice Studs are built to provide long-lasting performance season after season.e) Versatility: While primarily designed for icy terrain, Ice Studs also offer enhanced traction on other difficult surfaces, such as packed snow or mud, extending their usability across various off-road conditions.5. Company Introduction & Vision:Founded in [Year], the company behind these groundbreaking Ice Studs is a leader in off-road vehicle accessories and has a passion for enhancing the thrill and safety of outdoor adventures. Committed to excellence and continuous innovation, the company's mission is to equip ATV enthusiasts with high-quality, reliable, and effective products. By prioritizing rider safety and satisfaction, they aim to revolutionize the way ATVs perform in challenging conditions, providing riders with a range of solutions that elevate their experiences to unmatched levels.Conclusion:As winter enthusiasts gear up for thrills and excitement on icy trails, the introduction of ATV Ice Studs comes as a game-changer. With the ability to dramatically improve traction, control, and safety on icy terrains, these metal studs offer ATV riders a new level of confidence and enjoyment. Thanks to the company's dedication and innovation, winter adventures on ATVs have never been more thrilling and secure.

Read More

High-Quality Carbide Wire Drawing Dies for Precision Manufacturing

Carbide Wire Drawing Dies have long been an essential tool in the manufacturing industry, providing companies with the ability to produce high-quality wire products that meet strict industry standards. The use of carbide in wire drawing dies has allowed for increased efficiency and precision in the wire drawing process, making it an essential component for many companies in the wire and cable industry.{Company Name}, a leading manufacturer of carbide wire drawing dies, has been at the forefront of innovation in the industry for over 30 years. With a commitment to producing top-quality products and a dedication to meeting the needs of their customers, {Company Name} has become a trusted partner for companies seeking reliable and efficient wire drawing solutions.The use of carbide in wire drawing dies has become increasingly popular in recent years, as companies seek to improve their manufacturing processes and produce high-quality wire products more efficiently. Carbide wire drawing dies offer a number of advantages over traditional die materials, including increased wear resistance, improved surface finish, and longer die life. These benefits contribute to cost savings for companies using carbide wire drawing dies, making them a valuable investment for any wire drawing operation.{Company Name} has been at the forefront of developing and producing high-quality carbide wire drawing dies, utilizing the latest technology and manufacturing processes to ensure the highest level of quality and performance. With a team of experienced engineers and technicians, {Company Name} has the expertise and knowledge to provide their customers with customized solutions that meet their specific wire drawing needs.In addition to their commitment to quality and innovation, {Company Name} also prioritizes environmental sustainability in their manufacturing processes. They have implemented eco-friendly practices and technologies in their production facilities, ensuring that their products are not only high-performing but also environmentally responsible.The demand for carbide wire drawing dies continues to grow as companies seek to improve their manufacturing processes and produce high-quality wire products more efficiently. {Company Name} has positioned itself as a leader in the industry, providing their customers with reliable and efficient wire drawing solutions that meet the highest standards of quality and performance.With a focus on innovation, quality, and sustainability, {Company Name} continues to be a trusted partner for companies in the wire and cable industry, providing them with the tools they need to succeed in today's competitive market. As the demand for high-quality wire products continues to grow, {Company Name} remains committed to meeting the needs of their customers and providing them with the best carbide wire drawing dies on the market.In conclusion, carbide wire drawing dies have become an essential tool for companies in the wire and cable industry, offering numerous advantages over traditional die materials. {Company Name} has been a leader in the development and production of high-quality carbide wire drawing dies, providing their customers with reliable and efficient solutions that meet the highest standards of quality and performance. With a commitment to innovation, quality, and sustainability, {Company Name} continues to be a trusted partner for companies seeking to improve their wire drawing processes and produce high-quality wire products more efficiently.

Read More

Unveiling the High-Performing Tungsten Carbide Drill Bits: A Game-Changer in Drilling Technology

Tungsten Carbide Drill Bits Revolutionize the Drilling IndustryDrilling is an essential process in various industries, such as construction, mining, and oil exploration. However, the efficiency and effectiveness of drilling have always been dependent on the quality and durability of the drill bits used. With the advent of Tungsten Carbide Drill Bits, the drilling industry has undergone a revolutionary shift, leading to increased productivity and improved outcomes. One company, which has been at the forefront of this innovation, has completely transformed the way drilling is conducted, and consequently, has gained a significant market share. {Insert Company Name}, a pioneer in the development and manufacturing of cutting-edge drilling tools, has single-handedly redefined the standards of the industry. Established in {insert year}, the company quickly gained recognition for its exceptional engineering capabilities. Over the years, {Company Name} has consistently introduced groundbreaking technologies, setting new benchmarks for performance and reliability.The remarkable success of {Company Name} can be attributed to its relentless focus on research and development. The company boasts a state-of-the-art facility, equipped with the latest machinery and testing equipment, enabling it to create innovative and superior-quality products. Additionally, {Company Name} has assembled a team of experienced engineers and technicians who are dedicated to enhancing drilling techniques through continuous improvement. The introduction of Tungsten Carbide Drill Bits by {Company Name} has been a game-changer. These drill bits are manufactured with a unique combination of Tungsten Carbide, a robust material known for its exceptional hardness and resistance to wear, and high-quality steel. The marriage of these two components has resulted in an unprecedented level of performance in the drilling industry.One of the key advantages of Tungsten Carbide Drill Bits is their enhanced durability. These bits exhibit remarkable resistance to abrasion, which significantly extends their lifespan compared to traditional drill bits. This durability translates into reduced maintenance costs and downtime, ultimately proving to be a cost-effective solution for drilling operations.Moreover, Tungsten Carbide Drill Bits are designed to handle the most demanding drilling tasks. Whether drilling through concrete, rock, or metal, these bits effortlessly penetrate the toughest surfaces, ensuring high precision and accuracy. This versatility and reliability have earned {Company Name}'s Tungsten Carbide Drill Bits a stellar reputation among industry professionals.In addition to their durability and versatility, {Company Name}'s Tungsten Carbide Drill Bits offer superior performance in terms of speed and efficiency. The cutting-edge design of these bits minimizes vibration, resulting in faster drilling speeds and increased productivity. This not only saves valuable time but also improves overall project turnaround.Furthermore, Tungsten Carbide Drill Bits have environmentally friendly attributes. Their exceptional strength allows for cleaner and more precise drilling, reducing the risk of collateral damage or wastage. This contributes to a safer and more sustainable drilling process, aligning with {Company Name}'s commitment to environmental stewardship.Going above and beyond drill bit manufacturing, {Company Name} also offers comprehensive technical support and services. The company's team of experts is readily available to provide guidance and assistance, ensuring customers derive the most value from their drilling operations. Through training programs and on-site support, {Company Name} reinforces its commitment to customer satisfaction.With its innovative Tungsten Carbide Drill Bits and unwavering dedication to excellence, {Company Name} has established itself as a leader in the drilling industry. The company's revolutionary approach, commitment to research and development, and comprehensive customer support have secured its position in the market. As the industry continues to evolve, {Company Name} stands poised to introduce further advancements, revolutionizing drilling techniques and setting new industry standards.

Read More

Enhance Safety and Traction with Scooter Tire Studs

Title: Enhance Safety and Performance with New Tire Studs for ScootersIntroduction:In a bid to provide scooter riders with improved safety and enhanced performance, an innovative product – Tire Studs for Scooters – has been introduced by a leading company in the automobile accessories industry. These easy-to-install studs offer increased grip and traction, particularly in icy or slippery conditions, thus minimizing the risk of accidents and ensuring riders have a smoother, more controlled riding experience. With their durable build and compatibility with a wide range of scooter models, these tire studs are set to revolutionize scooter riding in urban environments.I. Increased Safety on the Roads:Tire Studs for Scooters are engineered to provide riders with enhanced safety, especially when navigating through challenging weather conditions or uneven terrains. The studs are designed to securely attach to the scooter's tires, allowing riders to maintain better control and stability. The added grip helps prevent slips and skids, minimizing the possibility of accidents, and ultimately reducing the risk of injury for both riders and pedestrians.II. Superior Traction and Performance:The specialized design of these tire studs enables increased traction, providing riders with improved performance on various surfaces. With the studs in place, riders can confidently handle slippery roads, wet surfaces, or even loose gravel. This enhanced grip translates into smoother acceleration, precise braking, and better maneuverability, allowing riders to confidently tackle various terrains while maintaining complete control over their scooter.III. Easy Installation Process:Installing Tire Studs for Scooters is a hassle-free process that does not require any professional expertise. The studs come with clear instructions and can be easily attached to the tires using simple tools that are often found in most households. This accessibility ensures that scooter riders of all skill levels can take advantage of the improved safety and performance benefits provided by the studs.IV. Durability and Longevity:Durability is a key aspect of these tire studs. Constructed with robust and long-lasting materials, they are designed to withstand rigorous wear and tear. The studs' resistance to abrasions ensures they retain their grip and traction during extended periods of use. This longevity guarantees that riders can rely on the studs to perform consistently, all year round, without compromising safety or effectiveness.V. Compatibility Across Scooter Models:Tire Studs for Scooters are engineered to fit a wide range of scooter models currently available in the market. This broad compatibility ensures that riders of different scooter brands and sizes can benefit from the enhanced safety and performance offered by these tire studs. Additionally, their adjustable design allows for easy customization to accommodate specific tire sizes, ensuring a precise fit for each user.VI. Conclusion:In conclusion, the introduction of Tire Studs for Scooters provides a groundbreaking solution for enhancing safety and performance in the world of scooter riding. With their increased traction and grip, these studs allow riders to confidently navigate challenging conditions while experiencing improved control and stability. The easy installation process and long-lasting durability make them an ideal choice for scooter enthusiasts of all skill levels. Whether you are a daily commuter or an adventurous rider, Tire Studs for Scooters offer a solution that revolutionizes the way scooters are ridden, making urban mobility safer and more enjoyable.

Read More

Carbide Inserts: A Guide to CNC Turning and Tungsten Tools

Carbide Inserts are a crucial component in the manufacturing industry, and they play a significant role in various machining processes. These inserts are made from cemented carbide, which is a composite material generally used in cutting tools for machining.The company {} specializes in the production of high-quality carbide inserts, including CNC carbide inserts, turning inserts, and TNMG1604 carbide inserts. With a focus on precision engineering and innovation, the company has established itself as a leading manufacturer in the industry.Cemented carbide inserts are known for their durability and resistance to high temperatures, making them ideal for use in CNC machining and turning applications. These inserts are designed to withstand the rigors of heavy-duty cutting and provide long-lasting performance, ultimately reducing the need for frequent tool changes and increasing productivity.With a dedicated team of engineers and technicians, {} has developed a range of CNC inserts that are tailored to meet the specific needs of their customers. Whether it's precision turning, threading, or milling, the company offers a comprehensive selection of inserts that deliver exceptional results across a variety of machining operations.One of the key advantages of using carbide inserts is their ability to maintain sharp cutting edges for extended periods, resulting in consistently high-quality surface finishes. This is particularly important in applications where the surface roughness of the machined part is critical to the overall product quality.In addition to their superior cutting performance, carbide inserts are also known for their cost-effectiveness. By minimizing tool wear and reducing machining time, manufacturers can achieve significant cost savings while maintaining high levels of production efficiency.The company {} takes pride in its commitment to quality and continuous improvement. In order to ensure the highest level of precision and consistency, the company utilizes advanced manufacturing techniques and quality control processes throughout the production of its carbide inserts.Furthermore, {} understands the importance of staying ahead of the curve in terms of technological advancements in the industry. As such, the company invests heavily in research and development to continuously improve its product offerings and stay at the forefront of innovation.By collaborating with industry leaders and constantly seeking feedback from its customers, {} strives to develop cutting-edge solutions that address the evolving needs of the manufacturing sector.As a result of these efforts, the company has earned a reputation for delivering reliable, high-performance carbide inserts that contribute to the success of its customers' machining operations. With a focus on precision, durability, and cost-effectiveness, {} has become a trusted partner for manufacturers seeking to optimize their machining processes.In conclusion, carbide inserts are essential components in the manufacturing industry, and companies like {} are at the forefront of producing high-quality inserts for a wide range of applications. With a dedication to innovation and customer satisfaction, {} continues to play a vital role in driving the success of its customers in the ever-changing world of machining.

Read More

Ultimate Guide to Carbide End Mills: Types, Applications, and Benefits of Solid Carbide Cutting Tools

[CNN News Report]Title: Enhancing Precision and Efficiency: A Closer Look at Advanced Carbide End Mills and CNC Cutting ToolsIntroduction:In today's fast-paced manufacturing industry, companies around the world strive to push the boundaries of precision and efficiency. Among the tools revolutionizing machining processes are advanced carbide end mills and CNC cutting tools. These versatile tools play a pivotal role in creating intricate cuts, improving productivity, and ensuring top-notch quality. In this report, we will delve into the features, applications, and benefits of these cutting-edge tools, along with their impact on the industry.Carbide End Mills: Precision Machining at its FinestCarbide end mills have emerged as the go-to cutting tools for precision machining. Composed of tungsten carbide and cobalt, these tools are known for their exceptional hardness, wear resistance, and heat resistance. Their robust construction allows them to endure prolonged usage and deliver consistent results. Carbide end mills are available in various designs such as flat end mills, tapered end mills, and center cutting end mills, catering to specific requirements across a wide range of operations.Highlights of CNC Cutting Tools:The advent of Computer Numerical Control (CNC) cutting tools has transformed the manufacturing landscape. These automated tools, driven by computer programs, provide unparalleled precision and accuracy. CNC cutting tools, commonly used with carbide end mills, offer numerous benefits, including reduced human error, shorter production cycles, and the ability to produce intricate shapes with ease. This amalgamation of modern technology and high-quality cutting tools results in improved productivity and cost-effectiveness.Enhancing Productivity with Solid Carbide End Mills:Manufacturing processes heavily rely on solid carbide end mills due to their exceptional durability and performance. With excellent material removal rates and chip evacuation capabilities, solid carbide end mills excel in high-speed machining operations. These tools efficiently cut a wide range of materials, from metals to composites, ensuring smooth surfaces and superior finishing. Moreover, the ability to withstand high cutting forces prolongs tool life, reducing the need for frequent tool changes and thus increasing productivity.Applications and Industry Impact:Carbide end mills and CNC cutting tools find widespread applications across various industries. In the aerospace sector, these tools play a critical role in crafting intricate parts, reducing weight, and improving fuel efficiency. In the automotive industry, they aid in precision machining of engine components, transmission parts, and body panels. Carbide end mills are also pivotal in mold and die manufacturing, woodworking, and medical equipment fabrication, where precision and superior finishes are indispensable.Company Spotlight: At the forefront of carbide end mills and CNC cutting tools innovation is . With a rich history in manufacturing industry-leading cutting tools, it has positioned itself as a global player in the market. is dedicated to delivering top-quality tools that enhance precision, efficiency, and customer satisfaction. By employing advanced manufacturing techniques and focusing on continuous research and development, the company consistently introduces cutting-edge tools that meet the evolving demands of its vast customer base.Concluding Thoughts:Carbide end mills and CNC cutting tools are transforming the manufacturing landscape, enabling companies to achieve unprecedented levels of precision, efficiency, and productivity. With their exceptional durability, versatility, and performance, these tools have become indispensable in machining operations across various industries. As technology continues to evolve, companies like will play a crucial role in developing the next generation of cutting tools, further shaping the future of precision manufacturing.

Read More

Tungsten Carbide Cobalt: Advantages, Applications, and Key Properties

Title: Advanced Tungsten Carbide Cobalt Innovations Boost Productivity in Various IndustriesIntroduction:In today's rapidly evolving industries, the demand for high-performance materials that can withstand extreme conditions and increase productivity is on the rise. Tungsten Carbide Cobalt (WC-Co), a cutting-edge and highly versatile material, has emerged as a frontrunner in meeting these demands. With its exceptional hardness, wear resistance, and strength, combined with the expertise and dedication of innovative companies such as [Company Name], the applications of WC-Co have expanded across various sectors. This article explores the significance and potential of this remarkable material in revolutionizing industries worldwide.1. Introduction to Tungsten Carbide Cobalt:Tungsten Carbide Cobalt is a composite material composed of tungsten carbide particles bound together using cobalt as a binder phase. Renowned for its exceptional hardness, WC-Co offers remarkable resistance to wear, high temperature, and corrosion, making it ideal for a wide range of industrial and engineering applications. With a hardness comparable to diamonds, WC-Co is renowned for its long-lasting durability and superior performance.2. Applications of WC-Co in the Manufacturing Industry:The manufacturing industry has embraced the advantages of WC-Co for various applications. Cutting tools, such as drills, end mills, and inserts, made from WC-Co have proven to be highly effective due to their excellent wear resistance and superior cutting capabilities. By withstanding extreme heat and intense pressure, WC-Co cutting tools enable manufacturers to achieve high precision and enhance productivity.Additionally, WC-Co finds extensive use in the production of wear-resistant components, such as nozzles, valves, and seals. These components, when made from WC-Co, exhibit exceptional resistance to abrasion, ensuring longevity and reliability, even in harsh operating environments. This utilization of WC-Co significantly reduces downtime and maintenance costs for industries relying on wear-resistant components.3. WC-Co in the Oil and Gas Industry:The oil and gas industry demands materials capable of withstanding extreme conditions, including high pressure and corrosive environments. WC-Co, with its exceptional resistance to wear and corrosion, has become an indispensable material in this sector. Cutting tools and wear-resistant components made from WC-Co enable drilling operations to progress efficiently, minimizing downtime and increasing overall productivity.Moreover, WC-Co coatings, applied to drill bits and downhole components, provide improved wear resistance, reducing the need for frequent replacements, and contributing to significant cost savings. By enhancing equipment durability and performance, WC-Co plays a critical role in optimizing extraction processes in the oil and gas industry.4. WC-Co in the Aerospace Industry:The aerospace industry relies on materials that can endure extreme temperatures, high pressures, and intense mechanical stress. WC-Co's exceptional hardness and resistance to wear make it an ideal choice for producing aerospace components. Its utilization ranges from turbine blades and vanes to nozzles and seals, ensuring the reliability and efficiency of aircraft engines.Furthermore, WC-Co composite material is utilized in the production of cutting tools for machining aerospace-grade alloys and composites precisely. These tools, with their exceptional hardness and wear resistance, enable precise manufacturing processes, contributing to the high quality and cost-effectiveness of aerospace components.5. WC-Co in the Medical and Dental Field:WC-Co's exceptional properties extend to the medical and dental field, where it finds applications in the production of cutting tools, surgical instruments, and dental drills. With its hardness and resistance to wear, WC-Co surgical instruments provide healthcare professionals with reliable and durable tools that ensure precise procedures. Similarly, dental drills made from WC-Co contribute to efficient and accurate dental treatments.6. Company Spotlight: [Company Name]:[Company Name] has emerged as a pioneer in the development and manufacturing of high-quality Tungsten Carbide Cobalt products. With a mission to revolutionize industries through innovative solutions, the company has consistently raised the bar in the WC-Co sector. With state-of-the-art facilities and a dedicated team of experts, [Company Name] offers a diverse range of products tailored to meet specific industry requirements, ensuring customer satisfaction and success.Conclusion:Tungsten Carbide Cobalt (WC-Co) has become a game-changer in a variety of industries. Its exceptional hardness, wear resistance, and strength make it an ideal material for high-performance applications, where durability and precision are paramount. With companies like [Company Name] at the forefront of innovation, the potential applications of WC-Co continue to expand, revolutionizing industries worldwide and enhancing productivity across sectors.

Read More

Discover the Latest in Tungsten Carbide Button Innovation

[Company Introduction]ABC Carbide Manufacturing Co., Ltd. is a leading manufacturer of tungsten carbide buttons, based in ABC City, Country. With over 20 years of experience in the industry, the company has established itself as a trusted and reliable supplier of high-quality products to various sectors, including mining, construction, and oil and gas exploration.ABC Carbide Manufacturing Co., Ltd. prides itself on its advanced production facilities, cutting-edge technology, and a team of highly skilled professionals. The company's commitment to innovation and customer satisfaction has enabled it to build long-lasting partnerships with clients worldwide. From raw material sourcing to the final delivery of the finished products, ABC Carbide Manufacturing Co., Ltd. ensures meticulous attention to detail and stringent quality control measures at every stage of the manufacturing process.[News Content]Tungsten Carbide Button - Revolutionizing the Mining IndustryIn recent news, ABC Carbide Manufacturing Co., Ltd., a leading manufacturer of tungsten carbide buttons, has been experiencing significant growth due to the increasing demand from the mining industry. Tungsten carbide buttons, also known as tungsten carbide inserts, are essential components in mining drill bits, providing exceptional hardness and wear resistance for prolonged use in challenging environments.With advancements in exploration technology and the need for more efficient and productive mining operations, the demand for high-performance mining tools has surged. Tungsten carbide buttons have quickly become the preferred choice for mining companies worldwide, thanks to their exceptional properties and performance in drilling applications.Tungsten carbide buttons offer superior strength and durability, making them ideal for various drilling applications, including surface and underground mining, well drilling, and tunnel construction. Their extreme hardness enables them to endure extreme impact and wear, ensuring longevity and reduced downtime for mining operations.ABC Carbide Manufacturing Co., Ltd. has earned a reputable name in the industry for producing tungsten carbide buttons that exceed expectations. By utilizing state-of-the-art machinery and employing highly skilled technicians, the company manufactures buttons with precise dimensions, accurate shape, and optimal composition, ensuring superior drilling performance and maximum productivity.The quality of tungsten carbide buttons is crucial to the success of any mining operation. Poor-quality buttons can result in frequent tool replacement, increased maintenance costs, and decreased overall efficiency. ABC Carbide Manufacturing Co., Ltd.'s commitment to quality ensures that their buttons meet the highest standards, providing mining companies with reliable tools to accomplish their goals effectively.Moreover, ABC Carbide Manufacturing Co., Ltd. offers a wide range of tungsten carbide button designs, catering to various drilling requirements. The company's dedicated research and development team continually innovates new designs to enhance drilling efficiency, reduce energy consumption, and improve overall performance.As the mining industry continues to expand globally, the demand for tungsten carbide buttons is expected to grow exponentially. ABC Carbide Manufacturing Co., Ltd., with its advanced manufacturing capabilities and unwavering commitment to quality, is well-positioned to meet this increasing demand.In conclusion, tungsten carbide buttons are revolutionizing the mining industry, providing superior hardness, durability, and wear resistance for drilling applications. ABC Carbide Manufacturing Co., Ltd., as a leading manufacturer of these buttons, is ensuring that mining operations worldwide have access to high-quality tools that enhance productivity and efficiency. With its advanced technology and dedication to customer satisfaction, ABC Carbide Manufacturing Co., Ltd. remains at the forefront of the tungsten carbide button industry.

Read More

Carbide Plate and Its Impact on Various Industries: Find out more!

Title: Revolutionary Carbide Plate Redefines Industrial ApplicationsIntroduction:Carbide plates are an essential component in various industrial sectors, offering exceptional hardness, strength, and wear resistance. However, a groundbreaking development in carbide plate technology has been unveiled, promising to revolutionize industrial applications. This innovation comes from a leading manufacturing company with a rich history of engineering excellence, and their latest creation is set to transform industries.[Company Name] is a renowned global leader in precision engineering and manufacturing solutions. With their commitment to research and development, the company continues to push the boundaries of innovation. Their latest achievement involves the production of a cutting-edge carbide plate that outperforms existing solutions in terms of durability, reliability, and versatility.Breaking Barriers in Carbide Plate Technology:The newly developed carbide plate boasts an unmatched combination of hardness and toughness, resulting in enhanced performance across a range of applications. By utilizing state-of-the-art manufacturing techniques and advanced materials, [Company Name] has successfully created a product that surpasses traditional carbide plates in every aspect.Unparalleled Durability and Wear Resistance:The advanced carbide plate is designed to withstand extreme environmental conditions and high impact forces without compromising on performance. Its exceptional hardness and wear resistance ensure prolonged service life, reducing downtime and maintenance costs. This offers a significant advantage to industries that rely on robust equipment, such as mining, construction, and manufacturing.Versatile Applications and Customization:[Company Name]'s carbide plate caters to a diverse range of industrial needs. Its versatility allows it to be used in cutting tools, wear parts for machinery, molds, and a variety of other applications. Moreover, the company offers customization options, ensuring that the carbide plate meets specific dimensions, shapes, and performance requirements of individual industries.Environmental Responsibility:In addition to its superior performance, the groundbreaking carbide plate aligns with [Company Name]'s commitment to sustainability. The manufacturing process minimizes waste and energy consumption, reducing the environmental impact associated with its production. This attribute makes the product particularly attractive to businesses looking to enhance their eco-friendly practices.Collaborative Approach:[Company Name] encourages collaborative partnerships with various industries to ensure that their innovation aligns with real-world requirements. They actively seek feedback and suggestions from their clients and make improvements accordingly. This customer-centric approach enables the company to continually refine their products and deliver tailored solutions to diverse industries.Conclusion:[Company Name] has once again demonstrated its expertise by developing a revolutionary carbide plate that surpasses industry standards. The exceptional hardness, wear resistance, and versatility of this cutting-edge product make it an ideal choice for industries seeking durable solutions. As the company continues to explore new frontiers in precision engineering, their focus remains steadfast on delivering innovative products that redefine industrial applications and contribute to a sustainable future. With exceptional performance and a commitment to customer satisfaction, [Company Name] stands at the forefront of the carbide plate revolution.

Read More